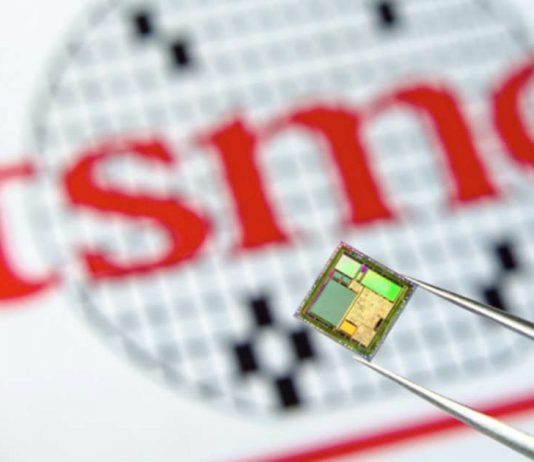

Taiwan Semiconductor Manufacturing Co. (TSMC), one of the largest chipmakers in the world, is having difficulties meeting the demand for 3nm chips from its top customer, Apple.

According to analysts surveyed by EE Times, TSMC has been struggling with tools and yields, which have prevented it from mass-producing its world-leading technology.

TSMC’s CEO, CC Wei, acknowledged that the company has yet to meet “customer demand,” which almost certainly refers to Apple. The manufacturer recently finished developing its 3nm process, and reports from December 2020 indicated that Apple had placed a full production order for its 3nm processors with TSMC.

However, TSMC is said to be delaying the introduction and ramp-up of 3nm due to the need to adopt multi-patterning with EUV lithography from tool supplier ASML. Analysts believe that TSMC will start ramping up production of Apple’s A17 and M3 processors on its N3 node in late 2023, with a yield of around 55%.

The delay in production is a setback for both TSMC and Apple, as it could lead to supply shortages and potentially impact the release date of upcoming Apple products. TSMC’s struggles with lithography tool troubles also highlight chip manufacturers’ challenges in developing and producing advanced technologies.

The next big step for TSMC is the 2nm chip, which is expected to enter production in 2025. The iPhone 17 is expected to be one of the first devices to adopt this upcoming process. However, TSMC must first overcome its current challenges in mass-producing its 3nm chips for Apple.

While TSMC is expected to ramp up production of Apple’s 3nm processors in late 2023, the delay could lead to supply shortages and potentially impact the release date of upcoming Apple products. The development of the 2nm chip is also an important milestone for TSMC, but it must first overcome the current challenges it faces in mass-producing its 3nm chips.